The 3406E 40 Pin ECM Wiring Diagram provides a detailed layout of the engine’s electronic control module‚ essential for troubleshooting‚ installation‚ and repair. It offers clear pin configurations‚ connections‚ and functional insights to ensure optimal performance and diagnose issues efficiently.

Overview of the 3406E Engine and ECM System

The 3406E engine is a high-performance diesel engine used in semi-trucks‚ generators‚ and marine applications. The Electronic Control Module (ECM) system manages engine operations‚ including fuel injection‚ timing‚ and emissions. The 40-pin ECM connector plays a crucial role in connecting sensors and components‚ ensuring precise control and monitoring of engine functions for optimal performance and reliability.

Importance of Wiring Diagrams for Troubleshooting and Repair

Importance of Wiring Diagrams for Troubleshooting and Repair

Wiring diagrams are essential tools for diagnosing and repairing issues in the 3406E ECM system. They provide a visual representation of connections‚ enabling technicians to identify faulty components‚ trace circuits‚ and verify voltage readings. This ensures accurate troubleshooting‚ reduces repair time‚ and minimizes the risk of further damage‚ making them indispensable for maintaining engine performance and reliability.

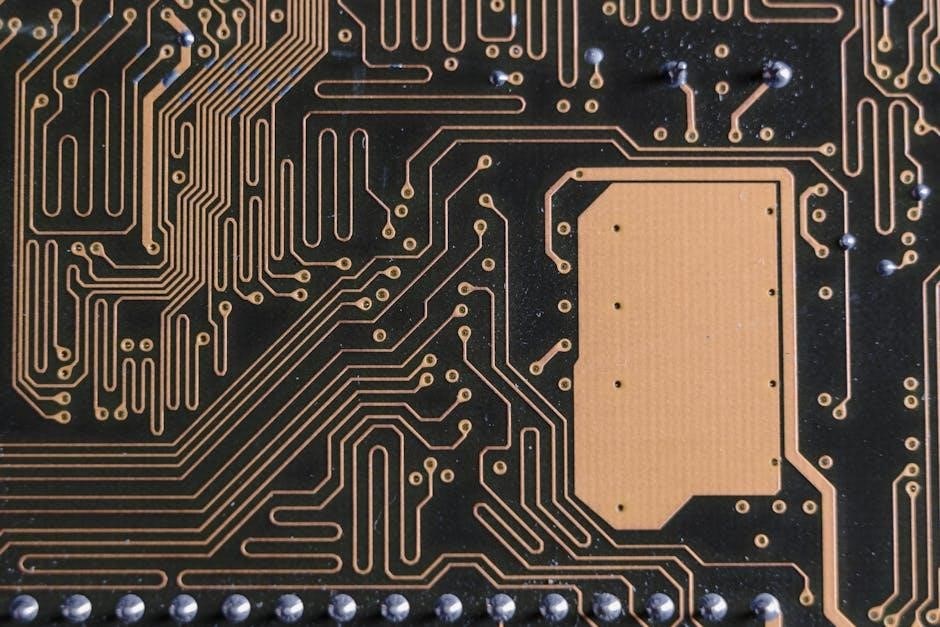

Key Features of the 3406E 40 Pin ECM Wiring Diagram

The diagram offers detailed pin configurations‚ connector information‚ and color coding‚ ensuring precise installation and troubleshooting of the ECM system for optimal engine performance and reliability.

Pin Configurations and Functionalities

The 3406E 40 Pin ECM Wiring Diagram outlines specific pin configurations‚ detailing functions for each connector. Pins 4‚ 10‚ 39‚ and 40 are crucial for vehicle speed signals‚ varying by ECM serial number (CA‚ CG‚ CJ). This setup aids technicians in diagnosing issues efficiently‚ ensuring accurate repairs and optimal engine performance.

Connector Information and Color Coding

The 3406E 40 Pin ECM Wiring Diagram provides detailed connector information‚ including pin numbers‚ functions‚ and color coding. Key connectors like J2/P2 are highlighted‚ with specific pins designated for functions like boost pressure sensors and engine speed signals. This standardized color coding ensures accurate wire identification‚ simplifying installation‚ troubleshooting‚ and repairs for technicians working with the ECM system.

Understanding the Pin Configuration

Understanding the pin configuration of the 3406E 40 Pin ECM is crucial for effective troubleshooting and system maintenance. Each pin’s layout and functionality are clearly defined‚ ensuring precise connections and operations‚ though variations may exist based on the ECM model.

Vehicle Speed Signal Routing Through Pins 4‚ 10‚ 39‚ and 40

The vehicle speed signal in the 3406E 40 Pin ECM routes through pins 4‚ 10‚ 39‚ and 40 for ECMs ending in CA. For ECMs ending in CG or CJ‚ pins 4 and 39 are used for Timing Calibration‚ while pins 10 and 40 remain unused. This routing is critical for accurate engine performance and diagnostics.

Differences in Pin Usage Based on ECM Serial Number (CA‚ CG‚ CJ)

ECM serial numbers significantly influence pin functionality. For CA-series ECMs‚ pins 4‚ 10‚ 39‚ and 40 handle the vehicle speed signal. In contrast‚ CG and CJ ECMs use pins 4 and 39 exclusively for Timing Calibration‚ rendering pins 10 and 40 inactive. Understanding these variations is essential for accurate diagnostics and repairs‚ ensuring proper ECM operation across different configurations.

Common Applications of the 3406E 40 Pin ECM Wiring Diagram

The 3406E 40 Pin ECM Wiring Diagram is widely used in semi-trucks‚ generators‚ marine engines‚ and other heavy machinery. It is essential for installation‚ troubleshooting‚ and repair processes.

Use in Semi-Trucks‚ Generators‚ and Marine Engines

The 3406E 40 Pin ECM Wiring Diagram is essential for semi-trucks‚ generators‚ and marine engines. It aids in troubleshooting‚ installation‚ and repair‚ ensuring optimal engine performance. For semi-trucks‚ it helps maintain proper engine control and diagnostics. Generators rely on it for accurate wiring and repair guidance. Marine engines use it for monitoring and repairing complex systems‚ ensuring reliability in demanding environments.

Relevance for Installation‚ Troubleshooting‚ and Repair

The 3406E 40 Pin ECM Wiring Diagram is crucial for installation‚ troubleshooting‚ and repair. It provides detailed pin configurations‚ enabling proper ECM installation and reducing errors. Technicians use it to identify faulty connections and diagnose issues efficiently. During repairs‚ it guides accurate component replacement and wiring adjustments‚ ensuring optimal engine performance and minimizing downtime in critical applications.

Troubleshooting with the Wiring Diagram

The 3406E 40 Pin ECM Wiring Diagram aids in identifying faulty connections and diagnosing ECM-related issues efficiently‚ ensuring accurate repairs and minimizing engine downtime.

Identifying Faulty Connections and Components

The 3406E 40 Pin ECM Wiring Diagram helps pinpoint faulty connections by detailing pin configurations‚ voltage readings‚ and component locations. Technicians can use it to visualize electrical circuits‚ trace wiring issues‚ and identify malfunctioning sensors or connectors. By cross-referencing the diagram with system errors‚ professionals can isolate faults efficiently‚ ensuring accurate repairs and minimizing engine downtime.

Steps for Diagnosing ECM-Related Issues

Begin by referencing the 3406E 40 Pin ECM Wiring Diagram to locate suspect pins and connections. Use a multimeter to check for proper voltage and continuity. Monitor ECM data streams with a scan tool to identify error codes. Inspect connectors for damage or corrosion and test component resistances. Replace faulty sensors or wiring as indicated by diagnostic findings to restore system functionality.

How to Read the Wiring Diagram

Interpret pin labels and connections to identify components. Analyze voltage readings and locate components using the diagram. Cross-reference with manufacturer guidelines for accurate understanding and troubleshooting.

Interpreting Pin Labels and Connections

Identify each pin label to understand its function‚ such as vehicle speed or sensor inputs. Examine connections to trace wiring routes and ensure proper component links. Use color coding and voltage readings to verify signal integrity. Cross-reference with the diagram to pinpoint issues and confirm compatibility with ECM serial numbers (CA‚ CG‚ CJ) for accurate troubleshooting and repair.

Understanding Voltage Readings and Component Locations

Analyze voltage readings at specific pins to diagnose issues. Locate components like sensors and solenoids using the diagram. Verify connections to ensure proper circuit functionality. Use the wiring diagram to identify component locations and validate signal outputs‚ ensuring accurate troubleshooting and efficient repairs for the 3406E ECM system.

Differences Between 40 Pin and 70 Pin ECM Systems

The 40-pin ECM is earlier‚ with specific configurations for vehicle speed and timing‚ while the 70-pin offers enhanced features and compatibility for modern systems‚ requiring careful upgrade consideration.

Comparison of Features and Functionalities

The 40-pin ECM focuses on essential engine control functions with specific pin assignments for vehicle speed and timing. The 70-pin ECM offers advanced features‚ including enhanced diagnostics‚ expanded sensor support‚ and improved compatibility with modern engines. While the 40-pin is tailored for older systems‚ the 70-pin provides greater flexibility and functionality for updated applications‚ making it a preferred choice for modern engine setups and diagnostics.

Upgrade Considerations and Compatibility

Upgrading from a 40-pin to a 70-pin ECM requires careful consideration of wiring harness compatibility and software updates. The 70-pin ECM offers advanced features but may not be backward-compatible with older systems. Ensure the wiring harness is updated to support the additional pins and functionalities. Professional installation is recommended to avoid system conflicts and ensure optimal performance. Compatibility checks are crucial before proceeding with any upgrade.

Resources for Obtaining the Wiring Diagram

The 3406E 40 Pin ECM Wiring Diagram PDF is available in service manuals and online sources. It can be easily downloaded from reliable platforms like eleccircs.com for detailed engine repair guidance.

Availability in Service Manuals and Online Sources

The 3406E 40 Pin ECM Wiring Diagram PDF is readily available in official Caterpillar service manuals and trusted online platforms. Websites like eleccircs;com offer downloadable versions‚ while forums and technical guides provide additional resources. The PDF includes detailed pin connections‚ component locations‚ and voltage readings‚ making it a comprehensive tool for technicians and engineers working with the 3406E engine system.

Recommended Websites and Technical Guides

For the 3406E 40 Pin ECM Wiring Diagram PDF‚ visit trusted sites like eleccircs.com for detailed schematics. Caterpillar’s official forums and technical guides are also excellent resources. These platforms offer reliable downloads‚ ensuring accurate and up-to-date information for technicians working with the 3406E engine’s electronic control module and wiring systems.

Tools and Equipment Needed for ECM Wiring

Essential tools include a multimeter‚ wiring harness‚ laptop with diagnostic software‚ and Torx(hex) keys. A crimping tool and wiring diagram are also crucial for accurate ECM connections and repairs.

Essential Tools for Installation and Repair

A multimeter is crucial for voltage and resistance checks. A wiring harness and crimping tool ensure secure connections. Torx/Hex keys are needed for ECM disassembly. Diagnostic software and a laptop aid in troubleshooting. A wiring diagram and service manual provide guidance. These tools help maintain electrical integrity and ensure accurate ECM connections and repairs.

Best Practices for Handling ECM Components

Always ground yourself to prevent static discharge. Use insulated tools to handle sensitive electronics. Clean connectors before installation to ensure proper connections. Avoid bending or flexing wires excessively. Label wires for easy identification. Store components in a dry‚ cool environment. Follow manufacturer guidelines for torque specifications when connecting pins. Regularly inspect wiring for wear or damage to maintain system reliability and performance.

Best Practices for ECM Installation and Maintenance

Ensure proper grounding and use protective covers for connectors. Avoid excessive force when connecting pins. Verify all connections are secure and clean before powering up. Regularly inspect wiring for damage or corrosion to maintain system integrity and performance.

Guidelines for Proper Wiring and Connector Care

Ensure all connections are secure and properly torqued to prevent damage. Clean connectors regularly to avoid corrosion. Avoid using excessive force when plugging or unplugging connectors. Use protective covers to shield connectors from environmental elements. Inspect wiring for signs of wear or damage before installation. Always follow the wiring diagram for accurate connections. Verify pin configurations match the ECM serial number specifications. Avoid bending or pinching wires‚ and ensure proper grounding for optimal performance. Regularly check for loose connections and tighten as needed. Use dielectric grease on terminals to prevent corrosion. Never use damaged or frayed wires‚ as this can lead to system malfunctions. Properly label and organize wires for ease of maintenance and future troubleshooting.

Preventative Measures to Avoid ECM Damage

- Inspect wiring for wear or damage before installation to prevent shorts or open circuits.

- Avoid using excessive force when connecting or disconnecting ECM connectors to prevent pin damage.

- Use protective covers on connectors to shield them from dust and moisture.

- Ensure proper grounding to prevent voltage fluctuations and electrical noise.

- Clean connectors regularly to avoid corrosion and poor connections.

- Apply dielectric grease to terminals to protect against corrosion and ensure reliable contact.

- Store ECM components in a dry‚ cool environment to prevent moisture damage.

- Avoid bending or pinching wires‚ as this can cause internal damage.